The Nichirei Group formulated the Nichirei Group Environmental Policy under the following theme: “If the Nichirei Group is to pass on to future generations the natural abundance that is the source of food and good health and to continue providing freshness and good taste—together with its stakeholders, it must use its superior products and first-class logistics network to reduce the environmental impact of its business activities throughout the entire supply chain and help create a sustainable society.”

The Nichirei Group Environmental Policy focuses on three priority issues: climate change initiatives, promotion of sustainable recycling, and symbiosis with nature. For climate change initiatives, we recognize that food and logistics companies are greatly affected by climate change. We are implementing the following initiatives as part of our low-carbon policies.

We support laws, regulations, and policies related to climate change mitigation and adaptation at our domestic and overseas sites. For example, in Japan we support Act on Promotion of Global Warming Countermeasures and Act on the Rational Use of Energy.

We have positioned efforts to address climate change as one of the material matters for realizing our long-term management goals toward 2030, and will actively work to achieve the Group's long-term CO₂ emissions reduction target.

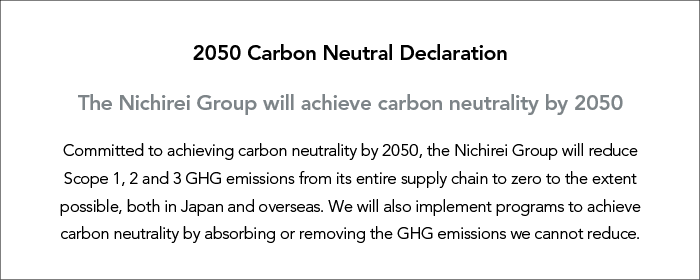

●Greenhouse Gas (GHG) Emissions

●CO₂ Emission Reduction Targets

| FY2024 Results | FY2025 Plan | FY2031 Targets | |||||

|---|---|---|---|---|---|---|---|

| Scope 1 and 2 in Japan and Overseas (Compared with FY2023) |

ー | ー | -42% | ||||

| Scope 3 in Japan and Overseas (Compared with FY2023) |

ー | ー | -25% | ||||

| Scope 1 and 2 in Japan (Compared with FY2016) |

-30% | -33% | -56%* |

●FY2024 GHG Emissions: 3,696 thousand tons-CO₂e in Japan and Overseas

●Nichirei Group Scope 3 Emissions by Category

Scope 3 emissions account for approximately 91% of the Nichirei Group’s total GHG emissions, and Category 1 accounts for approximately 87% of total Scope 3 emissions. We have confirmed that the main sources of emissions include procurement of raw materials and OEM products for use in processed foods, marine, meat and poultry products, and third-party logistics (3PL) transportation in the temperature-controlled logistics business.

| Scope 3 Category | FY2022 | FY2023 | FY2024* | |

|---|---|---|---|---|

| No. | Description | |||

| Category 1 | Purchased goods and services | 2,724,104 | 2,802,360 | 2,922,918 |

| Category 2 | Capital goods | 113,938 | 101,503 | 103,634 |

| Category 3 | Fuel- and energy-related emissions from activities not included in Scope 1 or Scope 2 | 62,828 | 65,438 | 66,566 |

| Category 4 | Upstream transportation and distribution | 98,016 | 95,991 | 115,389 |

| Category 5 | Waste generated in operations | 2,527 | 2,197 | 2,107 |

| Category 6 | Business travel | 505 | 1,563 | 1,235 |

| Category 7 | Employee commuting | 2,400 | 2,541 | 2,626 |

| Category 8 | Upstream leased assets | 0 | 0 | 0 |

| Category 9 | Downstream transportation and distribution | 3,519 | 3,696 | 10,524 |

| Category 10 | Processing of sold products | 33,833 | 37,563 | 76,262 |

| Category 11 | Use of sold products | 9,902 | 11,160 | 18,512 |

| Category 12 | End-of-life treatment of sold products | 16,431 | 15,519 | 20,263 |

| Category 13 | Downstream leased assets | 6,582 | 6,418 | 6,225 |

| Category 14 | Franchises | N/A | N/A | N/A |

| Category 15 | Investments | N/A | N/A | 16,931 |

| Total | 3,074,586 | 3,145,951 | 3,363,193 | |

●Nichirei Group’s Scope 1 and 2 CO₂ Emissions in Japan

In FY2025, we reduced our CO₂ emissions by 20% compared with FY2023.

The Nichirei Group is switching over to energy sources with lower CO₂ emissions. While switching to electricity from renewable energy sources with zero CO₂ emissions, we are also moving forward with initiatives to switch to fuels that produce low amounts of CO₂ when generating electricity or heat used for frying and baking on food factory production lines.

| Switching to Renewable Energy Sources for Generating Electricity | In FY2024, we achieved a 13 percentage-point increase compared with FY2023. This increase resulted mainly from increased use of renewable energy in the Funabashi Hinode area, where the Funabashi Plant of Nichirei Foods and Funabashi DC of Logistics Network Inc. are located. |

|---|

●Electricity from Renewable Energy Sources (%)

| FY2022 | FY2023 | FY2024 |

|---|---|---|

| 5 | 9 | 22 |

The Nichirei Group is installing solar power generation equipment on the premises of food factories and on the rooftops of refrigerated distribution warehouses. As of March 31, 2024, fifteen Nichirei Group facilities in Japan had installed solar power equipment that generated 4,268 MWh of electricity and reduced CO₂ emissions by 1,842 tons. In addition, through our intranet we are also sharing information such as locations that have installed solar panels and daily power generation volume to help increase employee interest in renewable energy and CO₂ emissions reduction.

●Solar Power Generation and CO₂ Emission Reduction

| Year of installation | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | FY2025 |

|---|---|---|---|---|---|---|

| No. of locations where installed (Cumulative total) | 8 | 9 | 10 | 11 | 15 | 17 |

| Power generated (MWh) | 2,068 | 2,149 | 2,974 | 3,201 | 4,268 | 6,798 |

| CO₂ emission reduction (Tons) | 1,003 | 986 | 1,408 | 1,429 | 1,842 | 2,876 |

●Nichirei Group Locations with Solar Power Generation Equipment

| Nichirei Foods | ・Funabashi Plant ・Shiroishi Plant ・Yamagata Plant ・Nichirei Ice Inc. Oizumi Ice Plant ・Kyurei |

|---|---|

| Nichirei Logistics Group | ・Sugito DC ・Matsue DC ・Kushiro DC ・Sakishima DC ・Higashi-Ogishima DC ・Nagoya minato DC ・Sendai DC ・Funabshi DC ・Daikoku DC ・Honmoku DC ・Kobe Rokko DC ・Fukuokahigashihama DC |

| Nichirei Biosciences | ・Global Innovation Center |

Sakishima DC

Sakishima DC Matsue DC

Matsue DC Kushiro DC

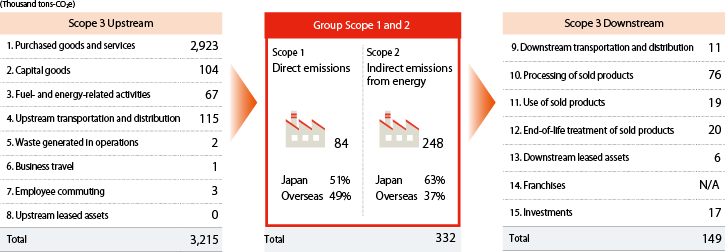

Kushiro DC●Supply of Power from Off-site Corporate PPA Services

The Nichirei Group has begun using off-site corporate PPA services that employ low-voltage solar power generation. We expect this initiative to reduce CO₂ emissions by approximately 2,000 tons annually. The Group will also increase procurement of renewable energy by expanding the use of these services to other areas, centered on the Kanto and Kansai regions.

The Nichirei Group is also working to use 100% renewable energy for electricity at its operating locations. In FY2023, two of the Nichirei Logistics Group’s operating locations that have solar power generation equipment achieved 100% carbon-free electricity, including the purchase of feed-in tariff (FIT) non-fossil fuel energy certificates.*1 In FY2024, the Group will complement these initiatives in working to use 100% renewable energy electricity. We will install rooftop solar power generation equipment at the Nichirei Group’s main campus in the Hinode area of Funabashi City, Chiba Prefecture. In addition, we will procure renewable energy through methods including Renewable Energy Certificates (RECs) and FIT non-fossil fuel energy certificates.

Since March 2020, Nichirei Foods has been purchasing RECs (Renewable Energy Certificate) and has switched to hydroelectric, biomass, and other sources of renewable energy for the electricity used to manufacture certain household-use frozen foods and for the total amount of electricity used at production facilities.

Kyurei Inc.’s new plant, which opened in spring 2023, takes care of all of its electricity needs with its own solar power generation facilities as well as renewable energy power sources including biomass.

In addition, in FY2021, the Head Office building (Nichirei Higashi Ginza Bldg.) shifted to renewable energy (making use of RECs) for all of its power usage. Furthermore, we employed RECs for all of the electricity used for the Nichirei Ladies professional golf tournament we hosted in June 2023.

●Renewable Energy Initiatives at Nichirei Foods Factories

| Plant | Funabashi Plant | Yamagata Plant | Kyurei | |

|---|---|---|---|---|

| Renewable energy procurement | Application | All electricity used for producing Honkaku-Itame-Chahan | All electricity used at the plant | All electricity used at the plant |

| Initiative | Purchase of RECs | Switch to renewable energy from hydropower generation | Switch to renewable energy generation from biomass and others | |

| Date initiated | March 2020 (ongoing) | February 2022 (ongoing) | April 2023 (ongoing) | |

| Installation of solar panels | Yes | Yes | Yes | |

Nichirei Logistics Group began operating electric trucks for refrigerated and frozen cargo in February 2023. Logistics Network Inc. has been using the three vehicles for deliveries in the Tokyo metropolitan area to reduce CO₂ emissions as it builds know-how on the operation of low-temperature electric trucks, which are rare in Japan, to prepare for their full-scale introduction in the future. In July 2023, two more vehicles began operating in the Tokai region. We will continue working to reduce our environmental impact in order to achieve sustainable logistics for supporting our customers’ supply chains.

Refrigerated and freezer electric trucks

Refrigerated and freezer electric trucks Send-off ceremony for the trucks

Send-off ceremony for the trucksThe Nichirei Group’s initiatives to counter climate change include systematically eliminating the use of fluorocarbons by switching to natural refrigerants for refrigeration equipment.

By 2030, we will have switched to natural refrigerants for 75% of equipment used by Nichirei Logistics Group (based on tons of equipment excluding leased equipment), including overseas facilities, and 100% of the freezers used by Nichirei Foods at its food factories and investee factories in Japan.

Refrigeration Equipment Using Natural Refrigerants (ammonia)

Refrigeration Equipment Using Natural Refrigerants (ammonia)●Target for Natural Refrigerants Conversion Rate

| FY2023 results | FY2024 results | FY2025 plans | FY2031 targets | |

|---|---|---|---|---|

| Rate of conversion to natural refrigerants Production equipment (Japan) |

56% | 63% | 74% | 100% |

| Rate of conversion to natural refrigerants Logistics (Global) |

53% | 56% | 61% | 75% |

| Fiscal Year | Factory / Logistics Center | Subsidy projects utilized |

|---|---|---|

| FY2014 | Logistics Network Sugito TC | Subsidies for businesses that rationalize energy usage |

| FY2015 | ・Nichirei Logistics Kansai Sakishima DC ・SCG Nichirei Logistics Co., Ltd. (Thailand) |

― |

| FY2016 | ・Logistics Network Funabashi DC 8th Expansion Building ・Nichirei Logistics Tokai Shiratori DC 8th Expansion Building |

Program for applying advanced technologies to promote wider application of equipment using energy-saving natural refrigerant |

| FY2017 | ・Nichirei Logistics Chushikoku Takamatsu-Nishi DC 2nd Building ・Nichirei Logistics Tokai Haruhi DC 2nd Building ・Logistics Network Funabashi DC 4th and 9th Building |

Program for applying advanced technologies to promote wider application of equipment using energy-saving natural refrigerant |

| FY2018 | ・Nichirei Logistics Tohoku Sendai DC 1st Building ・Nichirei Logistics Tohoku Morioka DC 2nd Building ・Nichirei Logistics Kanto Mito DC 1st Building |

Project to promote energy-efficient commercial refrigeration and air conditioning, for the creation of a CFC-free society |

| FY2019 | ・Nichirei Logistics Kyushu Kagoshima Futo DC 1st Building ・Nichirei Logistics Kyushu, Inc.: Naha Shinko Logistics Center |

Project to Accelerate Introduction of Energy Saving-Type Natural Refrigerant Equipment To Realize Fluorocarbon-Free and Low Carbon Society |

| FY2020 | <Nichirei Logistics Group> ・Nichirei Logistics Hokkaido, Inc.: Sapporo Oyachi DC 2nd Building ・Nichirei Logistics Tokai, Inc.: Haruhi DC 1st Building ・Nichirei Logistics Kansai, Inc: Osaka Shinnanko DC 2nd Building ・Nichirei Logistics Tokai, Inc.: Nagoya Minato Logistics Center <Nichirei Foods> ・Nichirei Foods Inc.: Kansai Plant |

Project to Accelerate Introduction of Energy Saving-Type Natural Refrigerant Equipment To Realize Fluorocarbon-Free and Low Carbon Society |

| FY2021 | <Nichirei Logistics Group> ・Nichirei Logistics Kansai, Inc.: Umemachi Logistics Center ・Nichirei Logistics Chushikoku, Inc.: Ujina Logistics Center ・Nichirei Logistics Chushikoku, Inc.: Matsuyama Logistics Center ・Nichirei Logistics Kyushu, Inc.: Kokura Logistics Center ・Kyokurei Inc.: Honmoku Logistics Center <Nichirei Foods> ・Nichirei Foods Inc.: Yamagata Plant ・Nichirei Foods Inc.: Kansai Plant |

Project to accelerate the introduction of energy-saving natural refrigerants in equipment for the early realization of a CFC-free, low-carbon society |

| FY2022 | <Nichirei Logistics Group> ・Nichirei Logistics Tohoku, Inc.: Sendai Logistics Center ・Nichirei Logistics Tokai, Inc.: Komaki Logistics Center ・Nichirei Logistics Tokai, Inc.: Mie Logistics Center ・Nichirei Logistics Chushikoku, Inc.: Ujina Logistics Center ・Nichirei Logistics Chushikoku, Inc.: Takamatsu Higashi Logistics Center ・Nichirei Logistics Kyushu, Inc.: Hakozaki Wharf Logistics Center <Nichirei Foods> ・Nichirei Foods Inc.: Shiroishi Plant |

Project to accelerate the introduction of energy-saving natural refrigerants in equipment for the early realization of a CFC-free, low-carbon society |

| FY2023 | <Nichirei Logistics Group> ・Nichirei Logistics Hokkaido, Inc.: Otaru Logistics Center ・Nichirei Logistics Tokai, Inc.: Shiratori Logistics Center ・Nichirei Logistics Kansai, Inc: Umemachi Logistics Center ・Nichirei Logistics Chushikoku, Inc.: Matsuyama Logistics Center ・Kyokurei Inc.: Daikoku Logistics Center |

Project to accelerate the introduction of energy-saving natural refrigerants in equipment for the early realization of a CFC-free, low-carbon society |

| FY2024 | <Nichirei Logistics Group> ・Nichirei Logistics Hokkaido, Inc.: Kushiro Logistics Center ・Nichirei Logistics Tohoku, Inc.: Morioka Logistics Center ・Nichirei Logistics Kansai, Inc: Takatsuki Logistics Center ・Nichirei Logistics Chushikoku, Inc.: Naruto Logistics Center ・Logistics Network, Inc.:Sugito Logistics Center ・Logistics Network, Inc.:Mito Logistics Center ・Kyokurei Inc.: Kobe Rokko Logistics Center <Nichirei Foods> ・Nichirei Foods Inc.: Funabashi Plant ・CHUREI Co., Ltd. |

<Nichirei Logistics Group> Project to promote a CFC-free and decarbonisation of refrigeration and freezing equipment that supports the cold chain <Nichirei Foods> Project to accelerate the introduction of energy-saving natural refrigerants in equipment for the early realization of a CFC-free, low-carbon society |

| FY2025 | <Nichirei Logistics Group> ・Nichirei Logistics Tokai, Inc.: Shimizu Logistics Center ・Nichirei Logistics Kyushu, Inc.: Miyakonojo Logistics Center ・Logistics Network, Inc.:Funabashi Logistics Center <Nichirei Foods> ・Nichirei Foods Inc.: Shiroishi Plant ・CHUREI Co., Ltd. ・Kyurei Inc. |

<Nichirei Logistics Group> Project to promote a CFC-free and decarbonisation of refrigeration and freezing equipment that supports the cold chain <Nichirei Foods> Project to accelerate the introduction of energy-saving natural refrigerants in equipment for the early realization of a CFC-free, low-carbon society |

The Nichirei Group owns large-scale refrigerated distribution warehouses and food factories, and is implementing various initiatives to increase energy efficiency. In addition, we conduct rigorous inspections and management on a daily basis to prevent fluorocarbon leakage. We also introduced high-performance fluorocarbon detectors in FY2022, and conduct regular inspections to reduce refrigerant leakage.

| Freezer upgrades | Appropriate renovation of compressors and coolers |

|---|---|

| Optimization of cooling tower settings | Suppression of freezer pressure level and reduction of cooling tower operating time |

| Prevention of warm air infiltration | Installation of warm air exhaust equipment and installation of appropriate dock shelters |

| Early detection and elimination of refrigerant leaks | Introduction of high-performance fluorocarbon detectors |

The Nichirei Logistics Group is stringently checking equipment to reduce refrigerant leaks at all domestic centers.

In FY2014, the Group installed high-sensitivity detectors, which are 10 times more accurate than those previously used, and can detect even minor leaks. By managing the amount of refrigerant used and eliminating leaks, the Group can achieve near-optimum equipment functioning. At the same time, the Group is working to avoid the unnecessary use of electricity. The Group has non-regular staff carry out inspections, since they notice energy-saving points that regular staff may overlook. Energy-saving inspections of the entire center are conducted in parallel with the refrigerant checks as both contribute to CO₂ reduction and the prevention of global warming.

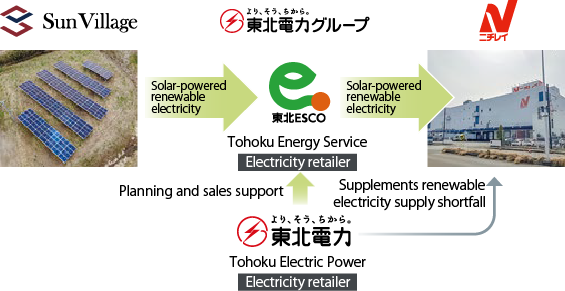

Since September 2018, the Nichirei Logistics Group has been conducting a joint demonstration in collaboration with Hitachi, Ltd. at Funabashi DC, utilizing state-of-the-art IoT technology for the early diagnosis of faults in refrigeration equipment and to improve the efficiency of equipment operations and maintenance. Visualizing energy consumption and analyzing operational improvements will assist the high-efficiency operation of cold storage facilities and will help reduce CO₂ emissions.

●Conceptual Diagram of Joint Demonstration

On June 28, 2024, the Nichirei Logistics Group received the "Special Award" at the 25th Logistics Environment Awards, hosted by Japan Association for Logistics and Transport.

●Special Award: Jointly Awarded to Uoroku Co., Ltd., Logistics Network Co., Ltd., and Synops Co., Ltd. for "CO₂ Reduction by Extended Lead Time Using Order Forecasting System"

As part of their logistics improvement efforts, the three companies collaborated to utilize an order forecasting system. They analyzed and minimized the impact of extended lead times, resulting in improved loading efficiency and work productivity. This initiative also reduced delivery vehicles and waiting times, and reduced CO₂ emissions.

●Special Award: Logistics Network Co., Ltd. and Nichirei Logistics Group Regional Companies for "CO₂ Reduction Using the Next-Generation Transportation System "SULS*""

Since FY2023, Nichirei Logistics Group has implemented the next-generation transportation system "SULS" at its self-operated bases nationwide. This system utilizes their proprietary refrigerated trailers, capable of carrying 24 pallets and featuring detachable loading platforms. By conducting pre-loading operations, they reduced driver loading times and vehicle waiting times. Additionally, improving efficiency by increasing the load capacity from 16 to 24 pallets, contributing to CO₂ reduction.

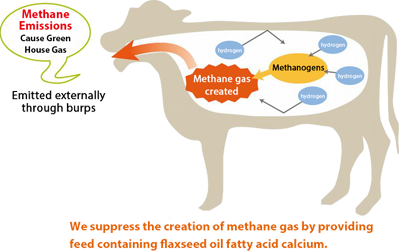

Ruminants, such as cattle and sheep, are known for their production of methane gas, which has 21 times the greenhouse effects of CO₂. The gas is produced in their stomachs, released internally when their food is broken down and digested, and then release externally. Since prevention of global warming has become a worldwide issue, Nichirei is undertaking the suppression of methane gas emissions produced by cattle.

The hydrogen generated by the activity of microbes in the rumen (the first stomach) during the digestive process is turned into methane gas by methanogen, and released externally through burps. If cattle are given flaxseed oil fatty acid calcium*1, the hydrogen in their rumen combines with the unsaturated fatty acids in the oil to form saturated fatty acids. Since research results show that methane gas production can be suppressed, to this end Nichirei has been testing crossbred cattle (male Wagyu and female dairy cattle) on domestic farms since FY2010.

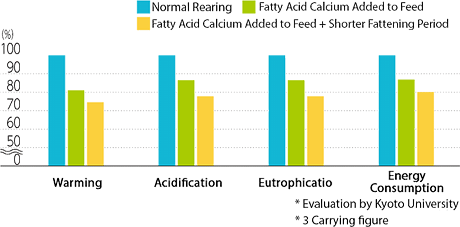

Using Kyoto University’s life-cycle assessment (LCA)*2 method developed in 2010 to gauge fattening methods, Nichirei has been able to confirm that the environmental impact of these crossbred cattle is 10% less than when conventional fattening methods are used. Further, there is an improved omega balance*3, while feed costs are lower due to the shorter fattening period resulting from improved growth*4. Nichirei is now moving toward the sale of beef produced through a nationwide rearing program using flaxseed oil fatty acid calcium. In addition to cross-breeding, Nichirei is also expanding this production method to crossbred Wagyu and Holstein cattle (bulls).

●Methane Gas Production

●Evaluation of Impact on Global Environment

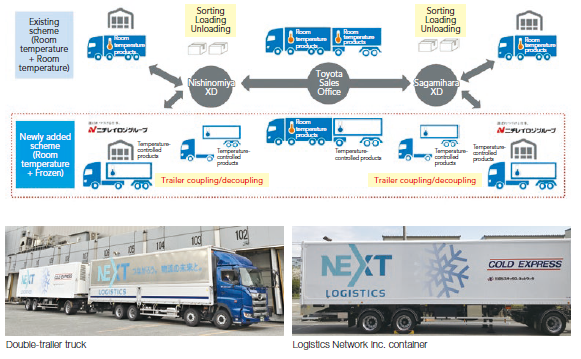

Nichirei Logistics Group, together with NEXT Logistics Japan, Ltd. (NLJ), started Japan’s first simultaneous bulk transport of frozen and room-temperature products using double-trailer trucks in March 2021. These 25-meter double-trailer trucks feature a room-temperature trailer coupled directly to the tractor, towing a refrigerated trailer. These trucks operate between relay points (XD centers) in the Kanto and Kansai regions.

●Operating Scheme

Double-trailer truck

Double-trailer truck Logistics Network Inc. container

Logistics Network Inc. container●Enabling Transport of the Load of Two Conventional Trucks in a Single Trip

By improving transportation and delivery efficiency, double-trailer truck operation can also be used to cope with the problem of Japan’s shortage of drivers, which has become serious. Combining frozen and room-temperature products for transport in a double-trailer truck enables one driver to transport the load carried by two conventional trucks. Moreover, simply coupling and decoupling the second trailer from the tractor enables simultaneous transportation of two different loads, leading to a reduction in cargo handling work and waiting time at each XD center and substantially reducing the burden on drivers.

Going forward, we will confirm the benefits of this type of operation in areas such as labor saving and reduction of environmental impact. We also plan to increase the types of cargo that can be bundled and carried to promote the evolution of the high-efficiency trunk-route transport scheme that NLJ is building into a system that can be used by a wider range of shippers and transport companies.

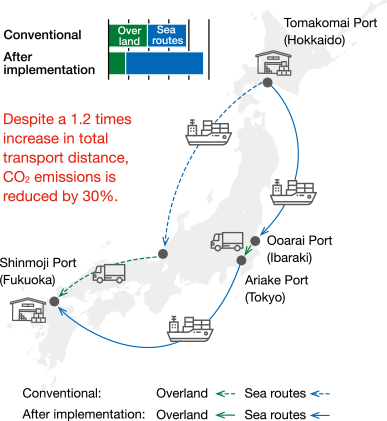

Since 2003, in a bid to reduce its environmental footprint, the Nichirei Logistics Group has been switching the means of transportation it uses from haulage by road to that by rail and sea. In 2009, the ferry transportation route from Hokkaido to Kyushu was extended, resulting in a 30% reduction*2 in CO₂ emissions.

In recognition of its achievements in expanding modal shift in frozen food shipping, the Nichirei Logistics Group’s Logistics Network received the Modal Shift Best Operator Award (Grand Prize) at the 14th Award for Excellent Business Entities Working on Modal Shift in 2016, and received the Green Logistics Partnership Meeting Outstanding Business Award*3 in 2017. Logistics Network is a third-party logistics (3PL) company that improves and manages all logistics operations for its shipper clients, from procurement and stock control to distribution. It has been promoting modal shift for more than 10 years. Rather than just simply using railways and ferries, it implements a variety of advanced solutions, such as having several shippers share a trunk line for transporting goods and making shipments more efficient and standardized by utilizing a demand forecasting system. In 2017, the company received the award along with Nichirei Foods (the owner of the cargo) and its partner companies, Ocean Trans Co., Ltd. and Nippon Express Co., Ltd. Going forward, we will continue to promote sustainable business management that reduces environmental impact and addresses labor shortages.

●Comparison of total transportation distances

Nichirei’s CO₂ reduction initiatives include developing CO₂ sinks and reducing emissions. In addition to managing green spaces on its properties, it participates in planting trees and flowers and weeding together with its neighbors.

Greening of the Kansai plant

Greening of the Kansai plant