Needs relating to good eating habits have been growing and diversifying among customers and within society at large. In the drive to further strengthen its core competencies and proactively resolve social issues, Nichirei will leverage its production technologies and expertise, while drawing on new developments including those in AI, IoT, autonomous driving, and robotics.

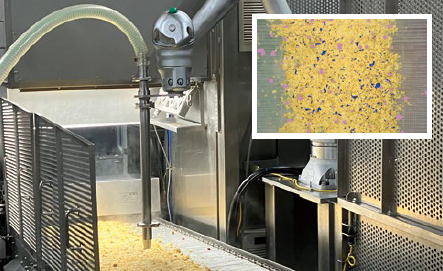

The new rice products plant of Kyurei Inc., one of Nichirei Foods Group companies, in Munakata City, Fukuoka Prefecture began operation in April 2023, with a production capacity of approximately 70 tons per day. We have also introduced the latest equipment and ramped up initiatives for eco-friendliness and automation. Environmental measures to reduce CO₂ emissions include using refrigerators that use natural refrigerants instead of CFCs, installing solar panels on the roof and utilizing renewable energy. For automation, the plant has introduced inspection and disposal of burnt items using AI robots and high-performance cameras, in addition to automating unloading of raw materials, product pallet loading and pallet transportation.

Exterior of new plant

Exterior of new plant Quality control using AI robots and high-performance cameras

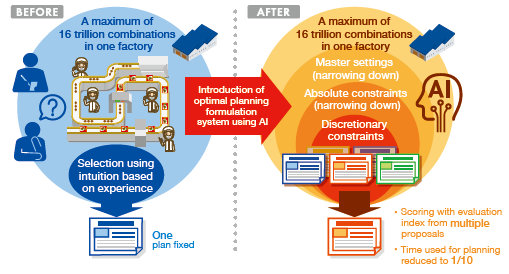

Quality control using AI robots and high-performance camerasNichirei Foods has collaborated with Hitachi, Ltd. in creating a system that uses AI to automate and optimize production and personnel planning. In FY2021, the system was introduced at two model factories in Japan. It uses sophisticated AI technology to reproduce and refine plans previously formulated by experts based on complex constraints. In addition to legal and regulatory requirements involved in personnel planning, a variety of other conditions must also be considered, including individual ability, overtime, and paid leave. Until now, experts formulated plans based on such preconditions, often relying on experience-based intuition. The new system uses AI to automate planning and identify optimal solutions from among the various permutations, while also quantifying and incorporating intuition-based criteria. As a result, planning requires one-tenth of the time and can be conducted by non-expert employees. The system is expected to contribute to work style reforms such as by reducing the number of hours worked and encouraging more employees to use paid leave. Given that in recent years food manufacturers have been called upon to make and supply products while responding to fluctuations in demand, the system is contributing to improved customer satisfaction due to its application of advanced digital technologies and the creation of efficient production systems. Nichirei Foods will continue to harness digital technologies to promote further improvements in productivity, reductions in lead time and inventories, as well as work style reforms.

●Production Planning Formulation Image

From a maximum of 16 trillion combinations in one factory, production plans encompassing daily production products and volumes for each line and personnel plans involving shift schedules are formulated automatically.

Following field tests, in FY2021 Nichirei Logistics Group began introducing an AI solution for automatically reading expiration dates from image data at 50 bases nationwide. As part of its efforts to fully digitalize warehouse operations, the Group has adopted tablet devices and is using AI solutions to enhance their functionality. Previously input manually, expiration date input can now be completed hands-free using AI, enabling highly accurate readings of 93% or higher and fast processing speeds of about two seconds. This has further improved quality control as it enables us to capture expiration date images and to then convert those images into data records, simplifying overall operations so that they can be performed by anyone, thus facilitating stress-free work.

In January 2018, Nichirei Logistics Group began conducting field tests of autonomous driving forklifts at refrigerated warehouses. In 2021, they were introduced at the Daikoku Distribution Center of Group company Kyokurei. A distinctive characteristic of autonomous driving forklifts is that they can be given instructions using a tablet device, thereby making safe operation possible for employees who might otherwise lack the physical strength or operating skills to manually operate a forklift. Going forward, we will steadily increase the number of facilities with autonomous driving forklifts and tie that measure into reducing working hours, economizing on manpower for on-site work, and improving occupational health and safety at our warehouses.

An autonomous driving forklift

An autonomous driving forklift AGV for transporting roll pallets

AGV for transporting roll pallets AGV for transporting pallets

AGV for transporting palletsNichirei Logistics Group Inc. collaborated with Telexistence Inc. to conduct a demonstration test in which Telexistence’s remote-controlled robot loaded mixed cargo on basket carts in the refrigerated area of a logistics facility.

The test confirmed the feasibility of creating a remote, stress-free work environment in logistics centers in which an operator in an office remotely controls a robot in a refrigerated area. The work involved the operator visually confirming each piece of cargo and its place of loading, them moving the robot and its arm by remote control.

We will continue to proactively introduce cutting-edge technology and digitalize operations in working to achieve sustainable logistics that support the supply chain.

Robot loading cargo

Robot loading cargo Robot operator using goggles

Robot operator using gogglesFurther refine the Nichirei Group’s core competencies in food processing, production and logistics to resolve social issues and improve profitability through competitive advantages in global markets.

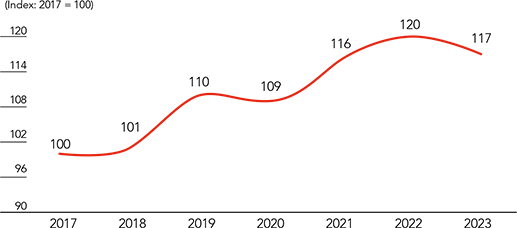

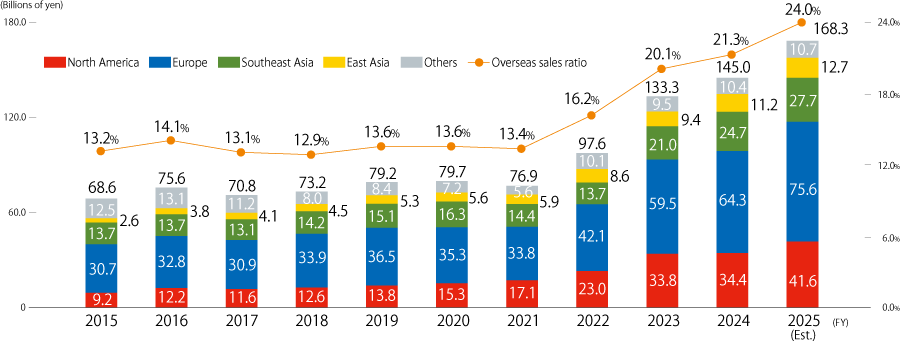

●Net Sales by Region (Overseas sales for all segments totaled by region)

●Integrating Production and Sales to Further Strengthen the Marketing-driven U.S. Business

Asian foods are becoming part of daily life in the United States due to the increasing Asian population, and the market continues to expand. With marketing capabilities that can anticipate local tastes and trends, InnovAsian Cuisine Enterprises Inc. (InnovAsian) has been outpacing market growth and building its presence as a driver of Nichirei Foods’ overseas business.

InnovAsian’s main categories are chicken, processed rice products, and appetizers, and easy access to Nichirei Foods’ technologies and insights is a major advantage. The Latino population of the United States is projected to exceed 30% of the country’s total population by 2050. Against this background, InnovAsian launched a Latin-inspired brand in the same three categories as its Asian foods. Sales began in spring 2024, and the company is working to create new demand.

Meanwhile, in 2022 we established our own plant for processed rice products in California. Utilizing Nichirei Foods’ strengths in processing and cooking technologies, the facility has built a production system that recreates the delicious flavors that meet local consumer needs.

We aim to capitalize on the continuing brisk food market in the United States and further expand business in terms of both production and sales.

Members of Nichirei Sacramento Foods Corporation, our plant in California

Members of Nichirei Sacramento Foods Corporation, our plant in California Nichirei Sacramento Foods Corporation

Nichirei Sacramento Foods Corporation Asian-inspired brand InnovAsian

Asian-inspired brand InnovAsian Latin-inspired brand DEL CORAZÓN

Latin-inspired brand DEL CORAZÓN●Contributing to Optimal Patient Treatment through Cancer Diagnosis

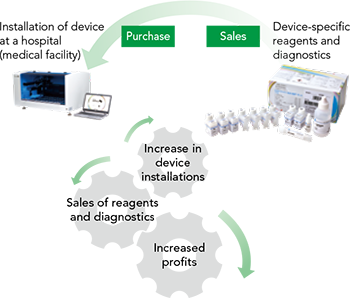

In 2019, we acquired Pathcom Systems Corporation (Pathcom), a U.S.-based medical device company that mainly sells products for cancer diagnosis in the United States and Europe. The number of cancer patients is increasing worldwide in tandem with the global increase in the elderly population. This in turn is expanding the market for immunohistochemical staining used in diagnosing cancer. Going forward, we will use Pathcom’s fully automated staining devices as a platform for the overseas rollout of a device-specific reagent sales model that integrates the development, production and sales of medical devices and diagnostic agents.

Nichirei Logistics Group’s European business began in 1988 with the acquisition of a cold storage company in Rotterdam, the Netherlands. From there, it expanded to Germany, Poland, France and the United Kingdom through mergers and acquisitions. Each European company is managed locally, and overseen by Nichirei Holding Holland B.V. (NHH), an intermediate holding company where Japanese employees from Nichirei Logistics Group have been stationed. While local management teams maintain their companies’ pre-M&A customers, brands and hiring practices, NHH’s responsibilities include monitoring the operations of European companies, formulating strategies, supporting their implementation, and strengthening governance. Through its years of experience, NHH has also developed the know-how and systems for M&A, including due diligence.

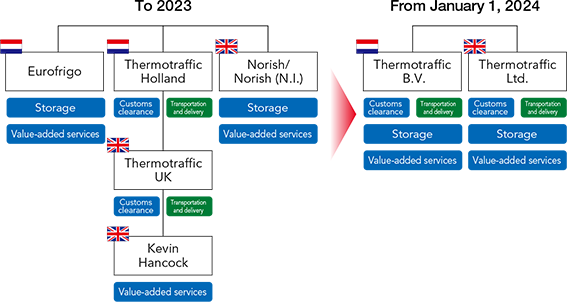

● Ramping Up Expansion of Our Competitive One-stop Services and Strengthening Our Business Base in Poland

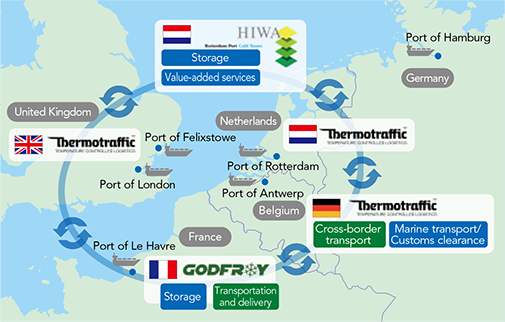

Our basic strategy for the temperature-controlled logistics business in Europe is to further expand our one-stop crossborder services that combine refrigerated storage functions at ports with services ranging from marine transport, drayage, customs clearance, and distribution processing to transportation and delivery. In January 2024, we reorganized our operations in the Netherlands and the United Kingdom. Objectives of the reorganization included ramping up the provision of one-stop services and sharing know-how across companies through an integration of the transportation and storage businesses, which had previously been run by separate companies. In May 2024, we also acquired a forwarding company in the United Kingdom.

In Poland, we have grown to a dominant position in the refrigerated logistics business for mass retailers. We expanded our warehouse in Znin in July 2024, and are scheduled to commence operations at a new warehouse in Warsaw in the fourth quarter of 2024.

We will leverage this enhanced coordination between functions in our ongoing efforts to expand our one-stop services and strengthen our business base in Poland.

●Leveraging Group Synergies to Increase Profits

●Adding More Value to Every Chicken Part and Further Expanding Global Sales Channels

GFPT Nichirei (Thailand) Co., Ltd. in Thailand has established a fully integrated system that takes in live chickens from joint venture poultry farms, slaughters and cuts them up into parts, then handles all steps from processing and cooking to freezing and packaging at directly connected processing plants. The company is able to stably procure and process safe and reliable raw materials, and makes various use of every part of the chicken.

Because preferences for chicken parts vary by country and region, we consider effective uses and sales channels to add value before sale. Sales channels extend worldwide. For example, thigh and breast meat are sent to Japan and Europe, where demand for these parts is high, wings are processed as feed for farmed fish, and feet are popular in China.

Currently, the company processes by-products such as organ meat and blood into poultry meal, and is stepping up sales to pet food manufacturers in Thailand. Because organ meat and other by-products are easily affected by market prices, increasing the level of processing helps to stabilize profits.

GFPT Nichirei (Thailand) Co., Ltd.

GFPT Nichirei (Thailand) Co., Ltd.●A Focus on Establishing a Base and Expanding Sales in Each Country

We are focused on establishing a base and expanding sales in each country in the ASEAN region. In 2023, we made our affiliates in Thailand and Malaysia into consolidated subsidiaries, expanding both the area and scale of the businesses. In Vietnam, a new facility began operation near Ho Chi Minh City in July 2024. Located in a rapidly growing industrial park, it is aimed at steadily capturing robust demand for storage of raw materials and products for factories.

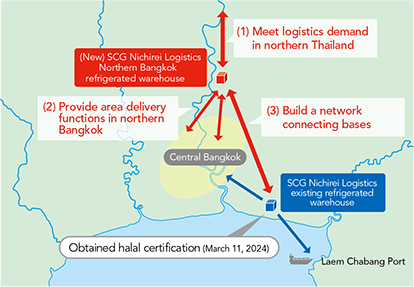

In Thailand, a new refrigerated warehouse is scheduled to start operation in spring 2025. It will target the brisk demand for temperature-controlled logistics in northern Bangkok, where food-related companies are concentrated. Our intention is to expand the business base in Thailand by increasing warehouse capacity and establishing a transportation and distribution network in the metropolitan area. Ultimately, we aim to develop operations linking Thailand, Malaysia and Vietnam.

Aiming to capture more storage and transportation demand by increasing warehouse capacity and establishing a transportation and distribution network in the metropolitan area

Aiming to capture more storage and transportation demand by increasing warehouse capacity and establishing a transportation and distribution network in the metropolitan area Aiming for stable operation of our new refrigerated warehouse by capturing growing demand for temperature-controlled logistics driven by Vietnam’s economic development

Aiming for stable operation of our new refrigerated warehouse by capturing growing demand for temperature-controlled logistics driven by Vietnam’s economic developmentAnnouncement of New business by establishing a joint venture in Vietnam

New Open of Distribution Center / Nichirei TBA Logistics Vietnam LLC

●Meeting Customer Needs with Advanced Processing Technology

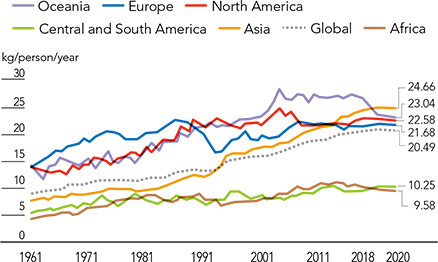

Global per capita consumption of seafood has doubled in the past 50 years, and is expected to continue increasing. In addition, market needs for seafood are diversifying, and we believe that precisely meeting those needs is our role, one that will ultimately lead to business growth.

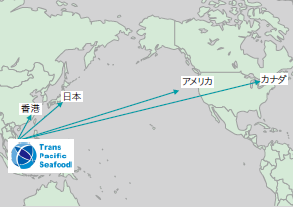

Established in Phan Thiet, Vietnam in July 2017, Trans Pacific Seafood Co., Ltd. (TPS) has continued to grow by processing raw materials procured using the capabilities we have been cultivating over the years into products that customers want. TPS currently has six production lines on a 20,000 m2 site, processing 2,000 tons of seafood annually with over 500 employees. In June 2024, a new freezer with a 2,000-ton storage capacity was completed to further stabilize quality and supply.

We will expand sales from TPS, the production base of our marine products business, not just to Japan but worldwide.

A processing line at the TPS plant

A processing line at the TPS plant

Expansion of overseas sales

Expansion of overseas sales MSC-certified crab products

MSC-certified crab products

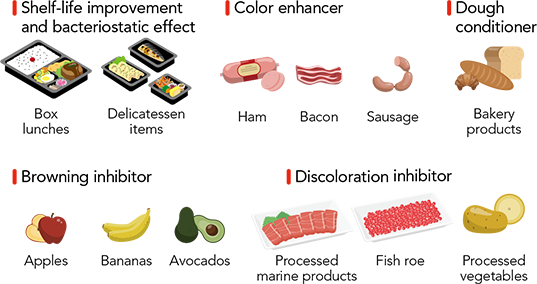

●A “Clean Label” Business Using Acerola, a Natural Source of Vitamin C

Acerola is rich in natural vitamin C and has a strong antioxidant effect. Nichirei was among the first to notice the potential of this ingredient, launching Acerola Drink in 1987. In 1991, we established Nichirei do Brasil Agricola Ltda. (Niagro) in Brazil, and successfully standardized the natural vitamin C content through independent research. As a result, products that contain Nichirei’s acerola ingredients can display labels with claims such as “One cup contains the recommended daily amount of vitamin C.”

To further expand this business, Niagro began producing Acerola powder in 2023. The “clean label” market, which calls for food prepared using simple raw materials and ingredients with easy-to-understand labeling, is growing worldwide due to environmental concerns and increasing food safety awareness and health consciousness. Acerola is attracting attention in the clean label market as an ingredient that is effective in preventing oxidation and browning. Acerola powder can also be used in bakery products and processed meats, allowing us to propose its use in a variety of business categories. Niagro is working to expand its business by assigning new sales representatives to the high-demand areas of Europe and North America to drive growth centered on Acerola powder. We aim to further develop the acerola business by harvesting raw materials in cooperation with contract growers, building a stable production system and conducting sales activities globally.