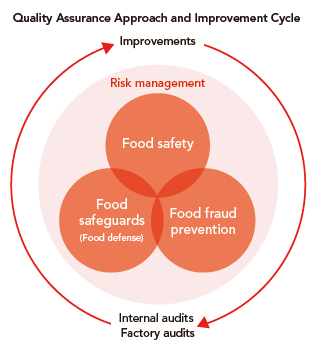

The Nichirei Group’s fundamental policies on quality assurance aim to ensure the quality and safety of the food products and services it provides, to prevent consumer health hazards, as well as to maintain and improve Company-wide quality management and assurance standards, and ensure customer satisfaction. In addition, to assess whether these initiatives are being implemented reliably, we use internal audits and quality audits at our factories based on our quality management system and food safety management system. We strive to upgrade our systems by following a PDCA cycle to facilitate improvements should any deficiencies arise.

●Quality Assurance Approach and Improvement Cycle

The Nichirei Group has established systems to properly manage and maintain the quality of the products and services it delivers at designated levels. We have established rules and standards for quality control and quality assurance, and perform internal audits and monitoring inspections based on our quality management standards to ensure that the Group’s quality management system is functioning effectively.

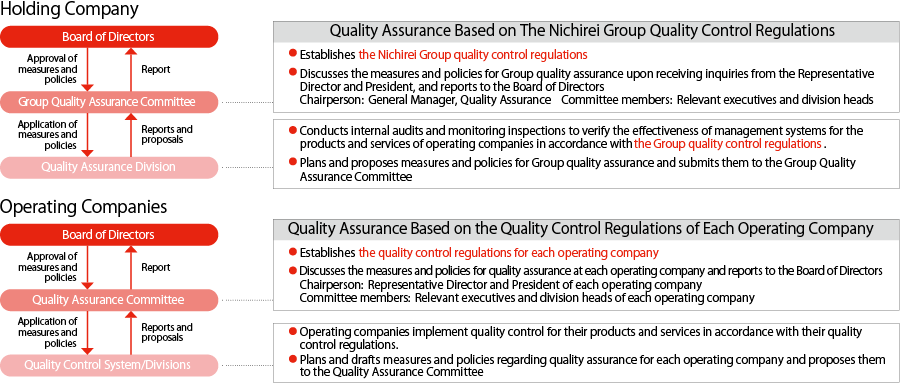

Each operating companyʼs Quality Assurance Division performs quality inspections of its own products and services and reports and shares its implementation status with the Quality Assurance Committee and the Group Quality Assurance Committee, which assists with the further revision and enhancement of its quality assurance system.

●The Nichirei Group Quality Assurance System Diagram

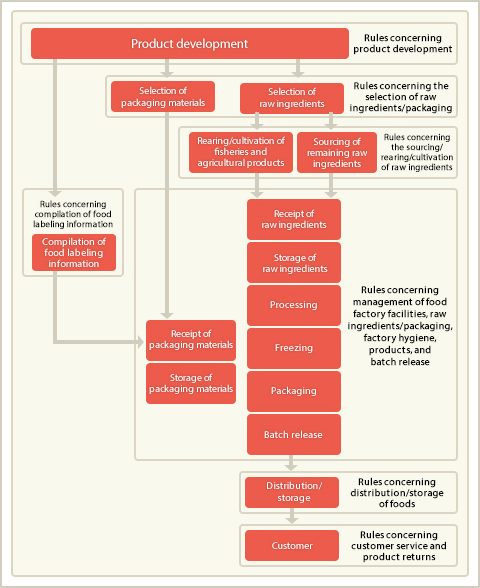

●Product Quality Assurance

The Nichirei Group offers a variety of products and services. Each operating company has established rules and standards based on the characteristics of the products and services it provides.

The establishment of these rules and standards is based on the hazard analysis and critical control points (HACCP) system. The Nichirei Group’s systematic preventative approach to food safety emphasizes the biological, chemical, and physical hazards in production processes and the need for a quality management system. This philosophy generally applies to all food products, and initiatives proceed according to its rules.

The Nichirei Group is working to increase the degree of food safety that it can ensure, through initiatives designed to protect food from intentional tainting that cannot be avoided using food safety initiatives, and crisis management initiatives, which allow accurate information to be revealed quickly in the event of an accident/incident leading to health hazards. It is also working to increase the degree of food safety that it can ensure, and expand its risk communication abilities during emergencies.

For factory audits, each operating company rationally and objectively evaluates the magnitude of risks based on various factors such as characteristics of products it handles, whether or not certification of international standards has been obtained and the quantity of products handled. Based on this evaluation, the operating company creates an annual plan according to which it carries out factory audits. Any concerns pointed out by the audits are reflected in factory improvement activities and Company-wide rule reviews. The PDCA cycle is also used in regular audits. Audit results are used as a reference when determining audit policies and target worksites when developing audit plans for the upcoming year.

| Quality Assurance Audit | FY2021 | FY2022 | FY2023 | FY2024 | FY2025 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Domestic | Overseas | Domestic | Overseas | Domestic | Overseas | Domestic | Overseas | Domestic | Overseas | |

| Number of factory/Site audits | 40 | 10 | 46 | 16 | 63 | 23 | 47 | 31 | 38 | 31 |

| Group Implementation Rate (Compared with plan) | 58% | 28% | 66% | 48% | 89% | 72% | 100% | 89% | 76% | 84% |

The Nichirei Group offers products and services with a variety of distinguishing characteristics. To evaluate and verify that management is being conducted in accordance with our fundamental policies on quality, we are actively promoting the introduction of the internationally recognized Food Safety Management System (FSMS) and working to strengthen our quality assurance system while providing safe products and services.

| Certification | Operating Company | Rate of Certification*4 | ||||

|---|---|---|---|---|---|---|

| FY2021 | FY2022 | FY2023 | FY2024 | FY2025 | ||

| ISO9001(Quality management system) | Nichirei Foods | 20.0% (3/15)*5 | 20.0% (3/15) | 0% (0/15) | 0% (0/15) | 0% (0/15) |

| Nichirei Fresh | 62.5% (5/8) | 62.5% (5/8) | 62.5% (5/8) | 33.3% (2/6) | 20.0% (1/5) | |

| Nichirei Logistics Group | 70.9% (83/117) | 73.5% (86/117) | 71.4% (85/119) | 73.1% (87/119) | 68.9% (82/119) | |

| FSSC22000*1、ISO22000*2、SQF*3(Food safety management system) | Nichirei Foods | 93.3% (14/15) | 100% (15/15) | 100% (15/15) | 100% (15/15) | 100% (15/15) |

| Nichirei Fresh | 100% (7/7) | 100% (7/7) | 100% (7/7) | 100% (6/6) | 100% (5/5) | |

| Nichirei Logistics Group | 1.7% (2/117) | 1.7% (2/117) | 1.7% (2/119) | 1.7% (2/119) | 1.7% (2/119) | |

| ISO14001(Environmental management system) | Nichirei Foods | 73.3% (11/15) | 66.7% (10/15) | 46.7% (7/15) | 13.3% (2/15) | 13.3% (2/15) |

| ISO13485(Medical devices and in vitro diagnostics) | Nichirei Biosciences | 100% (2/2) | 100% (2/2) | 100% (2/2) | 100% (2/2) | 100% (2/2) |

To prevent intentional contamination of food products, the Nichirei Group believes it is critically important to foster strong bonds of trust with employees at worksites, creating environments in which accidents are unlikely. Furthermore, it is necessary to employ both procedures and physical safeguards, as well as verification methods in the event of an accident. We have established food safeguard (food defense) systems tailored to each product type. In-house rules covering visitors and contractors, as well as self checks, are in place, and audits of our plants are conducted regularly to confirm safety. We are also working to improve the workplace environment based on employee satisfaction surveys and interviews. We have installed cameras and face recognition systems at all of our plants in Japan and overseas.

To protect the safety of food, we have created a system that is based on the distinguishing characteristics of each product and enables follow-up investigations should issues arise. If an issue does arise, a link is established with our food crisis management system, which facilitates the dissemination of accurate information and quick responses.

Based on this approach, we have established food safeguard systems tailored to each product type at each operating company. In addition to confirming safety through factory self-checks and factory audits, we are actively working to improve the workplace environment based on employee interviews.

●Nichirei Foods’ Four Principles of Food Defense

The Nichirei Logistics Group's newly built distribution centers are equipped with state-of-the-art facilities, including advanced security features and seismic isolation. In terms of quality, the center realizes advanced logistics quality through traceability and inventory management functions, in addition to temperature control that draws on the Group's expertise and technology. In our low-temperature logistics network, we support our nationwide distribution network by transporting and delivering approximately 4,000 trucks every day, including our own, and cooperation with transportation companies is essential. For this reason, we have established a cooperative association with transportation companies and have built a close cooperative relationship with them through driver contests, training, award programs, and other initiatives to improve safety and quality.

The logistics network of Nichirei Logistics Group and its partner companies in the Loginet Cooperative Association hold a driver contest to improve the safety skills of truck drivers. Drivers from six branches nationwide who advance through the preliminary rounds compete in their safety inspection skills and academic knowledge developed in their daily work. At the Eighth National Competition in FY2024, a woman driver won first place in the individual category for the first time. We remain committed to ensuring safe vehicle operation.

Loginet Cooperative Association Driver Contest National Competition (once a year: 8th year)

Loginet Cooperative Association Driver Contest National Competition (once a year: 8th year) All-Japan Forklift Driving Competition (held once a year every three years)

All-Japan Forklift Driving Competition (held once a year every three years) Judging of inspection skills

Judging of inspection skills Scene from the competition

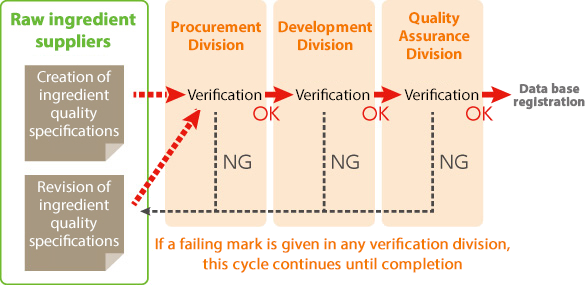

Scene from the competitionNichirei Foods researches the materials comprising the raw ingredients in three stages, and manages the distribution percentages, quality/microbial specifications, manufacturing process, and allergens contained. Raw ingredient suppliers are required to submit information on each ingredient in the form of ingredient quality specifications. This is placed in its database and used as the basis for nutritional information and to answer customer questions. When the Nichirei Group uses a new raw ingredient, it first evaluates the production facilities, confirms the ingredient quality, and checks samples. An overall assessment follows and, even after an ingredient has been approved for use, the Group continues to do factory evaluations, inspections, and factory improvements, to further enhance the ingredient. By checking the quality of an ingredient when it takes delivery, the Nichirei Group is able to verify the effect of its factory evaluations and inspections.

The Evaluation Flow for Ingredient Quality Specifications

To always provide safe, reliable and high-quality food, the Nichirei Group conducts rigorous quality control and inspections, from ingredients to final products and has built a traceability system suited to the distinguishing characteristics of each product. For example, in the event that an issue should arise in frozen vegetables, the cause can be investigated by using the product code symbol to trace the product back through the management records stored by the factory. In this way, it is possible to prevent the issue from spreading or recurring. We also provide prompt and accurate information to alleviate consumer concerns.

Building a traceability system requires collaboration and cooperation on the part of ingredient suppliers, manufacturers and distributors in our supply chain. The Nichirei Group regularly holds study sessions to deepen shared awareness with regard to quality-related information. To digitalize and link information, we are also promoting the utilization of our proprietary system for central control.

| Transporting raw materials | The farm manager (field person) checks the quantity of raw materials, status of pollution prevention measures, truck departure time, etc. and prepares an invoice. |

|---|---|

| Receipt of shipment at the factory | The person in charge of receiving the raw materials checks them against the invoice, and then labels the raw materials with the truck number. |

| Processing | Trace code labels are established for each process in the production line. Raw materials are processed in the order they arrive at the factory (raw materials are separated by production area). |

●Case Study of Frozen vegetable quality control

Nichirei Foods implements the following initiatives to ensure the quality and improve the safety of its frozen vegetables. These initiatives have helped Nichirei Foods to maintain zero violations due to the detection of pesticide residues during import customs clearance for 14 consecutive years.

The farms, in China and Thailand, where frozen vegetables are produced for Nichirei Foods have been selected based on their ability to meet Nichirei Foods’ environmental standards (in terms of soil, water quality, etc.) and agro-chemical management requirements. A farm advisor, from the Group’s frozen vegetable production facilities, is regularly sent to these farms to do on-the-spot checks of cultivation conditions and confirm that they are being adequately managed.

Nichirei Foods provides quality-management guidance for the contract factories that produce its frozen vegetables. Records are kept detailing the importation, selection, cleansing, processing, freezing, packaging, inspection, and shipping of the vegetables cultivated. In addition, the Nichirei Group makes sure with local inspection agencies that there are no problems regarding residual agrochemicals during pre-processing. During shipping it also checks that there are no problems with the production facility inspection divisions that have received technical training from Nichirei. Furthermore, the Nichirei Food Safety Center systematically inspects the hygiene and residual agrochemicals of domestic produce and certifies their safety at the same time as confirming the proper functioning of the local systems.

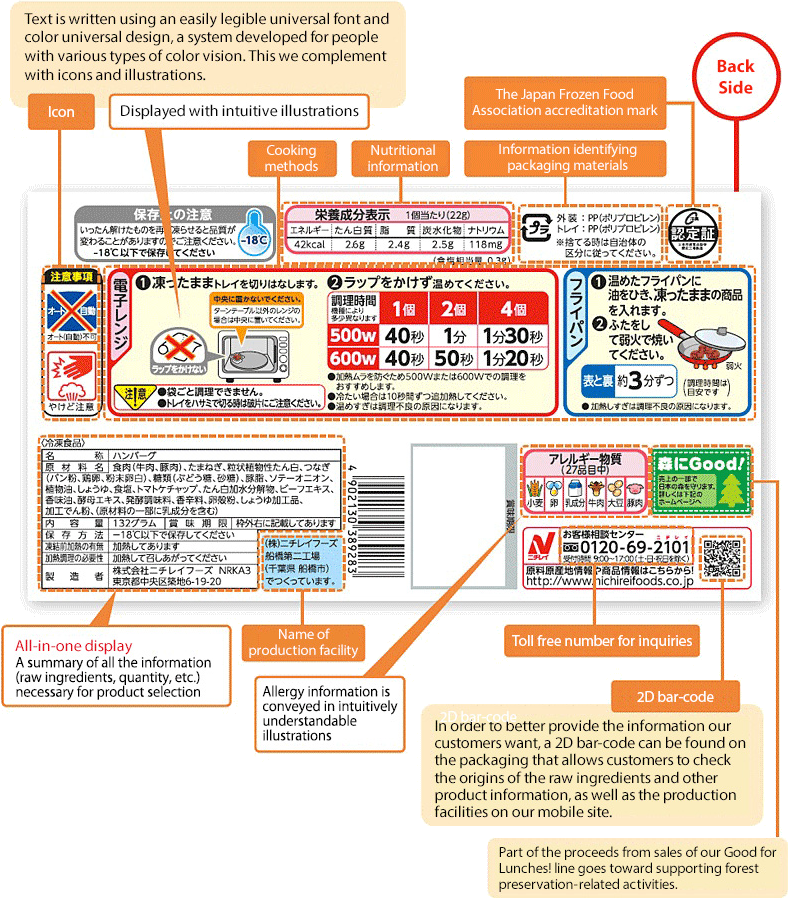

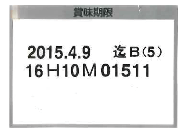

Besides providing products with reliable quality, providing relevant information to customers is Nichirei Foods’ top priority. Nichirei Foods has eliminated excessive advertising on its packaging and works to provide relevant information.

In addition, through the activities of its Customer Support Center, the Nichirei Group uses its customers’ opinions to provide feedback to work sites and improve quality.

A lot of information is concentrated on packaging. The information in the all-in-one displays on the side or back of packaging cannot afford to be mistaken, and thus undergoes stringent double-checking to ensure that all relevant legal stipulations are met. The name and place of origin of raw ingredients used in products are identified on the packaging, based on the information provided by the producers. Further, since the best-by date and lot number are displayed, it is possible to look up when and where a product was made, and which ingredients were used. Given the Group’s belief that a customer’s ability to communicate with lit is of paramount importance, packaging clearly displays a toll free number for enquiries.

In order to ensure the accuracy of information related to product safety and selection, the Nichirei Group conducts a number of checks between the time that information displays are created and products are shipped. It also checks to make sure that nothing on the packaging can cause misunderstanding. It is implementing display checks with these two points in mind in its examinations as well, and only those products that pass can be manufactured.

Display verification

Printing, data checks

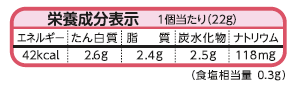

Currently, in Japan, 28 types of foods cause food allergies, 8 of which (shrimp, crab, walnut, wheat, buckwheat, eggs, milk, and peanuts) are required by the Food Labeling Act to be labeled due to the number of cases and severity of the allergic reaction.

The Nichirei Group investigates the raw materials used and the possibility of unintentional contamination during the manufacturing process before labeling food allergenic substances by the Food Labeling Act. In particular, Nichirei Foods has devised a list of food allergens contained in the frozen prepared foods for home use that we handle.

In order to obtain information about raw ingredients, the Nichirei Group requires suppliers to provide detailed specifications. But, before using these as a resource for product packaging, it runs tests to confirm they are correct. Such scrutiny of information, as is relevant to highly processed ingredients, can require several months. In addition, it adapts to changes in laws related to food product labeling as they arise.

Search for information on raw materials, place of origin, and allergies (Only Available in Japanese)

In FY2025, there were no violations of laws and regulations related to products and services.

As a company engaged in food-related businesses, the Nichirei Group believes that access to better nutrition is a very important part of people’s health. Nichirei Foods develops and sells wellness products that promote health. In addition, Nichirei Biosciences provides the public with academic and technical information related to immunostaining and has made it available to health professionals through an information website, allowing it to contribute to a healthy society through its businesses.

The Nichirei Group actively participates in industry group activities and contributes to helping communities improve and solve the issues they face through proposals and recommendations/encouragement.

Nichirei and Nichirei Foods are official members of the Japan Frozen Food Association, both Nichirei Logistics Group and its main subsidiaries are members of the Japan Association of Refrigerated Warehouses, and Nichirei is a member of the Japan Food Industry Association. In addition, Nichirei participates in the activities of the following organisations and others.

Japan Frozen Food Association (Only Available in Japanese)

Japan Association of Refrigerated Warehouses (Only Available in Japanese)

Japan Food Industry Association (Only Available in Japanese)

The Nichirei Foods Customer Support Center aims to improve customer satisfaction and corporate value through quickly and appropriately responding to the opinions and reports of customers. In addition, Nichirei aims to provide accurate product information and a brand that is both safe and reliable.

In order to improve customer service, the Customer Support Center runs customer satisfaction (CS) surveys.

When customers make a suggestion about a product, Nichirei sends them a report form and a survey postcard, both of which it has them return.

The survey uses a five-point scale to evaluate four areas: initial impression contacted by telephone (reception response); items noted by the respondent (on the report form); time taken to submit report (response time); and future purchasing intentions (repeat purchase). Space is also provided for customers to include additional comments. The aggregate results are used to improve Customer Support Center services. Efforts on this direction are ongoing.

●Breakdown of Customer Interactions in 2023

●Evaluation of Customer Satisfaction Reception Response

These are the product recalls that have occurred in the past five years.

| Date | The number of recall cases |

|---|---|

| FY2021 |

None |

| FY2022 |

None |

| FY2023 |

3 cases |

| FY2024 |

3 cases |

| FY2025 |

1 cases |

The Nichirei Group conducts training for quality assurance personnel at each operating company with the goal of enhancing their skills. In addition, the holding company conducts annual training on specific topics primarily for quality assurance personnel to enhance their food quality assurance awareness and capabilities.

| Training | Description | FY2021 | FY2022 | FY2023 | FY2024 | FY2025 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of People | Hours | Number of People | Hours | Number of People | Hours | Number of People | Hours | Number of People | Hours | |||

| Nichirei Foods | First- to third-year employee technical training session | Smooth communication, problem-solving technique, control of production line sanitation | 97 | 727 | 107 | 1,058 | 110 | 825 | 98 | 735 | 100 | 750 |

| Leader candidate training | Management demonstration on educating young employees and accomplishing tasks | 45 | 1,041 | 42 | 1,029 | 46 | 1,188 | 50 | 1225 | 25 | 1038 | |

| Training for obtaining FSSC 22000 certification | Explanation of the items for the FSSC 22000 standard, cultivation of internal auditors, how to create HACCP-related documentation | 20 | 140 | 91 | 547 | 62 | 497 | 131 | 712 | 143 | 330 | |

| Nichirei Fresh | First- to second-year employee training session | Basic knowledge of quality assurance, factory check, label, response to requests, etc. | 18 | 44 | 19 | 46 | 15 | 32 | 10 | 27 | 21 | 36 |

| Mid-career employee training (livestock instructor, livestock processed product meister) | Factory audit / guidance points, selected materials, mechanism of metal / X-ray detector, basics of cleaning and sterilization, label creation, etc. | 2 | 12 | 18 | 48 | 14 | 50 | 17 | 46 | 10 | 20 | |

| Plant Quality Manager Training | Improvement activities, insect and rodent control, laws and regulations, and presentations. | - | - | 30 | 180 | 31 | 146 | 21 | 252 | 17 | 259 | |

| Information session for revision of laws and regulations | Food labeling standards, addition of food allergies, etc. | 300 | 300 | - | - | - | - | - | - | - | - | |